Intertech Medical (USA) takes next step in automation and reaps rewards.

In August 2017, MAPP, the Manufacturers Association for Plastic Processors, awarded Intertech Medical first place for their 2017 Innovations Award for their work cell automating quality inspection, degating, and packaging. Intertech Medical, located in Denver, Colorado, is the region’s premier full service injection molder and contract manufacturer, specializing in medical devices.

The changes began after Intertech had been molding a medical part with complex geometry and features that was difficult to trace defects on using conventional inspection methods and sampling. With the part’s critical application and an expectation of zero defects, this was particularly problematic. After three customer complaints within six months, it was clear to both Intertech and their customer that a solution was needed.

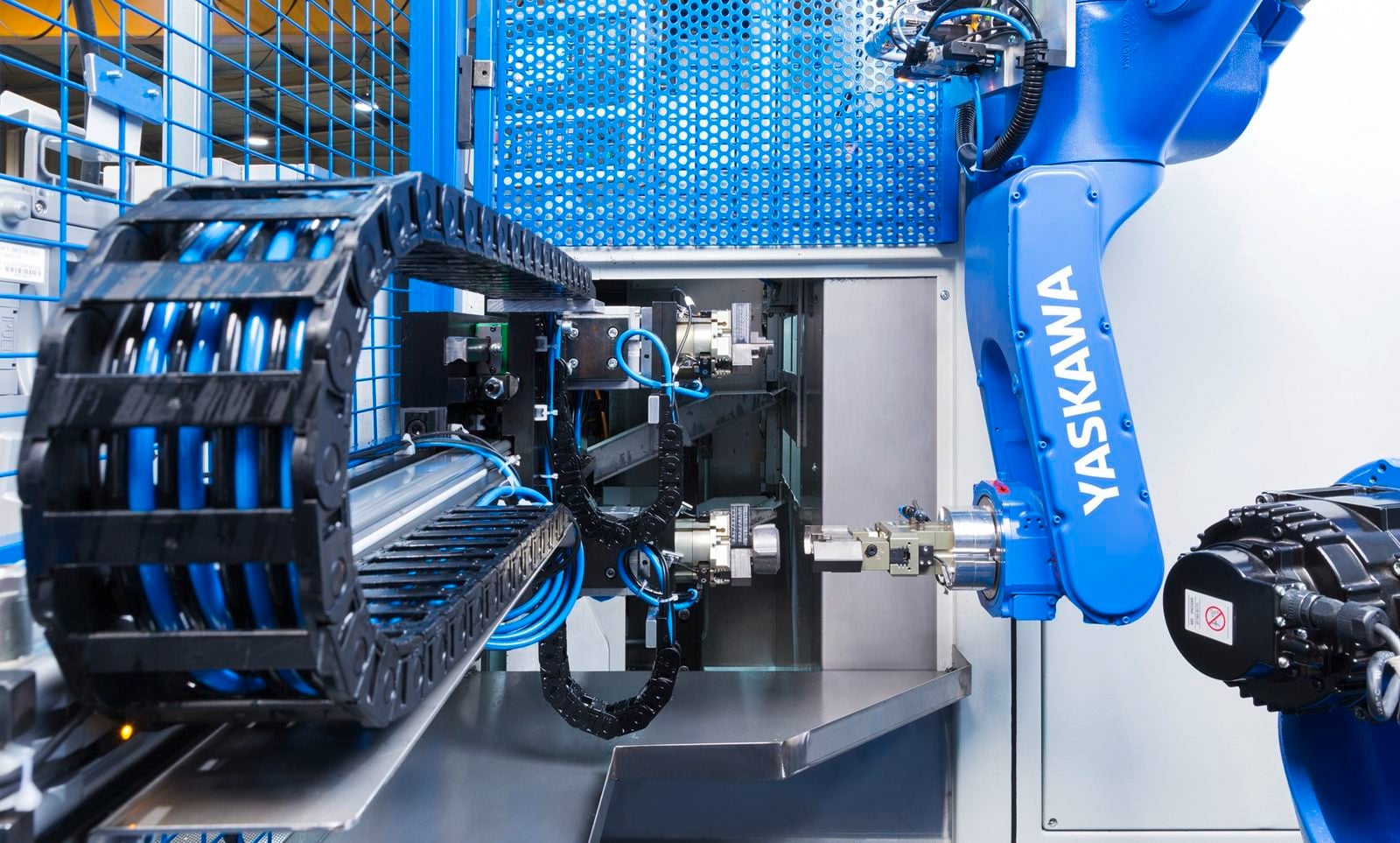

To solve the problem, Intertech designed and built a machine-side, automated work-cell that utilized integrated process control and quality control to get to zero defects. The solution primarily centered on integrated process control, automated quality inspection, and the reduction of bioburden from part handling and packaging. Rather than just adding more operators and increasing the number of times quality inspections, Intertech took a leap forward in their automation and inspection technology and were able to achieve the best results possible.

Successful WITTMANN automation

Intertech already had robots, but the supplier they had been using was limiting their ability to program and customize their process. Knowing that WITTMANN robots had a reputation for open architecture and flexibility, they reached out to see what they could do. WITTMANN BATTENFELD, INC., USA, initially setup a few complete automation cells, including robots, EOAT, downstream part orientation stations, and tray filling conveyor systems, to demonstrate their capabilities. The WITTMANN BATTENFELD employees stayed on site for a couple weeks, allowing them to provide extensive training on their systems. Intertech was then off and running, taking the reins from WITTMANN BATTENFELD. Their in-house engineering, automation, mold shop, and maintenance department used the programmability they had lacked before to create a new process and system that could exceed their customer’s needs.“We love what we are able to do with the WITTMANN robots,” said Kevin Clements, Director of Engineering at Intertech Medical. “The capabilities far exceed anything else we see in the market, from their SmartRemoval technology to the training and support that’s available when needed. With this automation in place, our company achieved ROI on the complete automation system in less than 9 months.”

Since the completion of this work cell, Intertech has had zero returns from their customer, and was ranked by their customer as a preferred supplier. The design was so successful that they have replicated the technology to three additional work cells, and they now have nine WITTMANN robots in their plant.